Inspection for raw material

Appearance:check whether it is milky white or light yellow, the shape is uniform or not.

Melt index:apply melt flow rate meter to get data

Carboxyl terminal:use titration device to test carboxyl terminal content

Our experienced quality inspectors conduct each inspection.Through this step-by-step process, inspectors will identify and correct any anomaly or quality defect quickly.

Appearance:check whether it is milky white or light yellow, the shape is uniform or not.

Melt index:apply melt flow rate meter to get data

Carboxyl terminal:use titration device to test carboxyl terminal content

Specification:Compare plate drawings with the order artwork

Appearance:Check whether it has any indentation on surface

Specification:compare the color and size of the packaging materials like carton,cardboard,etc..with the order artwork

Appearance:check the contents, pattern and surface based on the order requirements

Mass:check the weight and strength by measuring

Appearance:check the color, size, label and odor for the pellets

Melt index:check it by using flow rate tester

Mass:check the weight and strength by measuring

Specification:check weight, color pattern,adhesion based on the order requirement.

Appearance:guarantee no straight lines when tearing and no running lines, crystal points on the bag body

Specification:check size,thickness,weight and color based on the order requirement

Appearance:check whether the printed content is clear, whether the surface is dirty or has ink dots

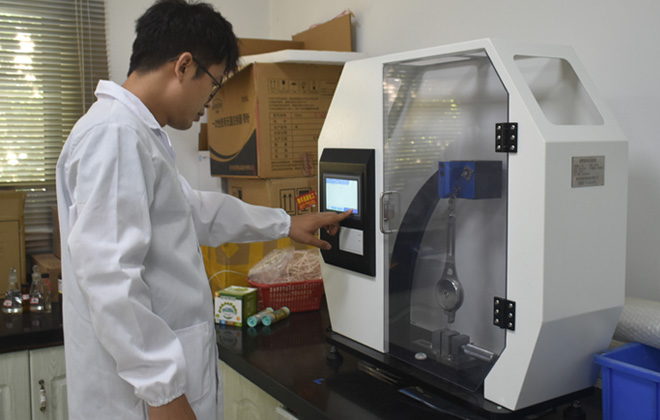

To guarantee each link can reach the production standards, we conduct inspection based on the IPQC system including self-inspection and random inspection, and then we send these qualified products to the inspection center for testing. It’s mainly consisted of:

Tensile force:use electronic tension machine to test tensile strength and elongation as well as its sealing strength

Tear resistance:use Elemendorff tear tester to test the force

Dart impact power:use falling Dart Impact Tester to test the power

Bearing force:use bag fatigue testing machine to test its force

To ensure our product can meet the shipping specifications and even your requirements, we need to comprehensively inspect the quality before the product is put into storage.

We mainly focus on appearance inspection and performance inspection including:

Specification of products:confirm whether it is consistent with your order requirement such as size, color, printed contents, odor, etc..

Product packaging method and contents:use Elemendorff tear tester to test the force

Dart impact power:check whether they are consistent with your order requirement, including its packaging appearance, weight, and thickness,etc..

Product performance:check its performance by water testing

To ensure the potential defects are detected before shipment and conformity with the order requirements, the out-going quality control is necessary. It includes:

Confirm batch number of the order

Confirm winding quantities and shipping quantities

Confirm printing and specification based on the order

Apply Statistical Process Control (SPC) to monitor and control the manufacturing process, and collect data at various stages of the manufacturing process and analyzing it to identify any variations from the set quality standards.

Perform visual and functional inspections as well as conduct reliable testing to ensure the quality.

Build up our own testing center with professional teams to control the standards of each inspection process.

TORISE provides you with quick quotation and free samples

Torise Biomaterials has always focused on the research and development of fully biodegradable resins and the professional production of compostable plastic bags, forming an efficient automated supply chain.

Learn More

Torise Biomaterials can provide personalized design and customization to ensure that your products perfectly match your brand image and deliver the finished product quickly.

Learn More

86-18151919890

86-0511-85598456